In the eyes of reporters, the 2006 heavy machinery industry had an unexpectedly gorgeous ending, which also indicates a more brilliant start in 2007. It seems that the past "silly and stupid" is no longer related to the heavy machinery industry. Heavy machinery has truly become a part of the equipment manufacturing industry. It can be described by the words "high-end" and "modernization".

From now on, heavy machinery can step on the international stage with its own strength, and calmly mark "MadeinChina". If anyone doesn't believe it, please take a look at the development of the heavy machinery industry in 2006. You will understand why 2007 is so exciting.

From the latest statistics of the industry, the economic growth rate of the heavy machinery industry in 2006 has remained at around 30%, and the profit has increased at a rate of 60%. It is expected that the total industrial output value of the industry will reach 270 billion to 280 billion yuan in 2005. The annual growth rate is 30%, and the total profit is nearly 15 billion yuan. In 2006, the total import and export volume exceeded 10 billion yuan. Since the first trade surplus in 2005, the import and export surplus in 2006 has exceeded 400 million yuan.

The original experts predicted that the situation of heavy machinery will have a proper fall in 2006. On the contrary, from the development trend of the whole industry in 2006, the heavy machinery industry not only has great development, but also saved more potential. It laid the foundation for two major changes that will emerge in 2007.

Wang Jianye, chairman of the China Heavy Machinery Industry Association, said that in 2007 the heavy machinery industry will usher in two substantial changes. First, the economic operation has changed from extensive to efficient, and second, technological progress has changed from imitation to innovation. These two changes are unprecedented.

The reason for these major changes is that some large enterprises have undergone technological transformation during the Tenth Five-Year Plan period, and the company has not forgotten the core of development. When the industry is in a downturn, many large-scale heavy machine companies still have not forgotten their research skills. As the industry has just improved, they have successively bought new equipment and improved equipment grades.

At the same time, enterprises pay attention to the cultivation of innovative mechanisms, actively establish technical engineering centers, give more rewards to innovative talents, and mobilize the enthusiasm of employees. With these foundations, companies have naturally embarked on a path of sound development.

In February 2006, the "Several Opinions of the State Council on Accelerating the Revitalization of Equipment Manufacturing Industry" was promulgated and implemented. Among them, several of the 16 key equipments for accelerating revitalization are related to the heavy machinery industry. It can be said that the promulgation of "Several Opinions" Once again, the development of the heavy machine industry is full of strength. In 2006, the National Development and Reform Commission also invested a fund to support the technological transformation of Yizhong Group and the Group.

In 2006, there were many equipments in the heavy machinery industry in China that reached the international leading level. The following is a summary of some of them.

"King of the rolling mill" settled in Baosteel

China's first 5-meter wide plate mill -- Baosteel's 5-meter mill was strictly tested by Baosteel users, SMS experts and two-way three-way mills in 2006. The performance of the mills met the technical requirements and passed the A inspection. This wide and heavy plate mill is called "the king of rolling mills". The maximum width of rolling is 5 meters and the maximum rolling force is 100,000 kN, which is the first in China.

The head of the 5-meter rolling mill project of the German SMS company said that the total weight of the 5-meter rolling mill mainframe is nearly 2,000 tons, up to 17 meters, and there are more than 20 parts of the rolling mill with more than 30 tons. Such a huge and complicated rolling mill is in the double There is no size adjustment in the assembly, which fully demonstrates that the dual manufacturing level is first class.

Large bridge machine and excavator come out

The Taiheng Group's 900-ton bridge machine and 27-cubic-meter excavator were also available. Too heavy success in the development of a 900-ton large bridge machine, this bridge machine has the new performance of the same kind of products that are not available in the tunnel, without disassembly, automatic shrinkage, etc., greatly improving the work efficiency.

China's first 27-cubic-meter large-scale mining excavator with complete intellectual property rights was developed by Taizhong Group, breaking the long-term monopoly of 20-50 cubic meters of large-scale mining excavators in China's open-pit coal mines by foreign companies. It is understood that this equipment has reached the advanced level of similar foreign products, but the price is only 70% of foreign products. The successful research and development of the above two products proves that too heavy indeed seizes the market opportunity.

Independent research and development of the first stacker and reclaimer

Shenyang Mining Machinery (Group) Co., Ltd. independently developed the first domestic top-end side picking and reclaiming machine with international advanced level, which realized industrialization and replaced imported. The product design solves the problem of the waste generated by the material yard. So far, Shenyang Mining Machinery (Group) has produced more than 700 piles and reclaimers, and its output value has reached more than 2 billion yuan.

7.63 m coke oven machinery against international rivals

7.63m coke oven machinery is a large-scale modern equipment equipped with advanced technology in the world. At present, only a few countries in the world can manufacture it, which is a new topic for Dalian Heavy Industry and Crane Group. Practice has proved that Dalian Heavy Industry and Crane Group is fully capable of competing with the world's strong players, and the localization of major equipment in the metallurgical industry has great potential.

At present, the second set of coke oven machinery produced by Dalian Heavy Industry and Crane Group is being commissioned by Maanshan Iron and Steel Group, and two sets of contracts have been signed with WISCO Group. The Shougang Group, which is undergoing relocation and transformation, is also preparing to purchase in Dalian Heavy Industry and Crane Group. 5 sets of such devices.

15,000 tons of hydraulic presses to create casting and forging bases

The 15,000-ton hydraulic press designed and manufactured by Yizhong has been put into use.

This 15,000-ton hydraulic press is the world's highest level, most capable, and most complex free-forging hydraulic press. It is designed, manufactured and installed by itself, and has independent intellectual property rights. In addition, the completion of the 15,000-ton hydraulic press has made Yizhong the largest production base for castings and forgings in Asia, marking a major breakthrough in adhering to independent innovation. The processing capacity and forging level of a major forging has also achieved leap-forward development. .

Multi-project development refreshes domestic records

Many major R&D projects of CITIC Heavy Machinery have completely refreshed domestic records.

Among them, the serialization and optimization design of the pure low-temperature waste heat power generation technology research project has been completed; the active lime complete set project with independent intellectual property rights is being further improved and expanded; the research and development of the daily production of 1,200 tons of active lime system host equipment, and began to alumina Expansion of fields such as calcium carbide and power plant desulfurization.

In the field of mills, in addition to the first LMGS4624 cement slag vertical mill with independent intellectual property rights in China, it also developed the largest 覫6.7×11.58m ball mill in China.

Developed a series of seed filters for the alumina industry with independent intellectual property rights and the largest domestic level in the world.

These highlights are just the beginning. Wang Jianye believes that if the national economic operation continues to maintain this good condition in 2006, the growth rate of the gross output value of the heavy machinery industry will not be lower than 20%, and the profit growth rate will be faster, reaching 50%. Most heavy machinery companies will completely get rid of the situation of low efficiency. In 2007, the heavy machinery industry will truly enter the foreign market and provide major equipment to the world.

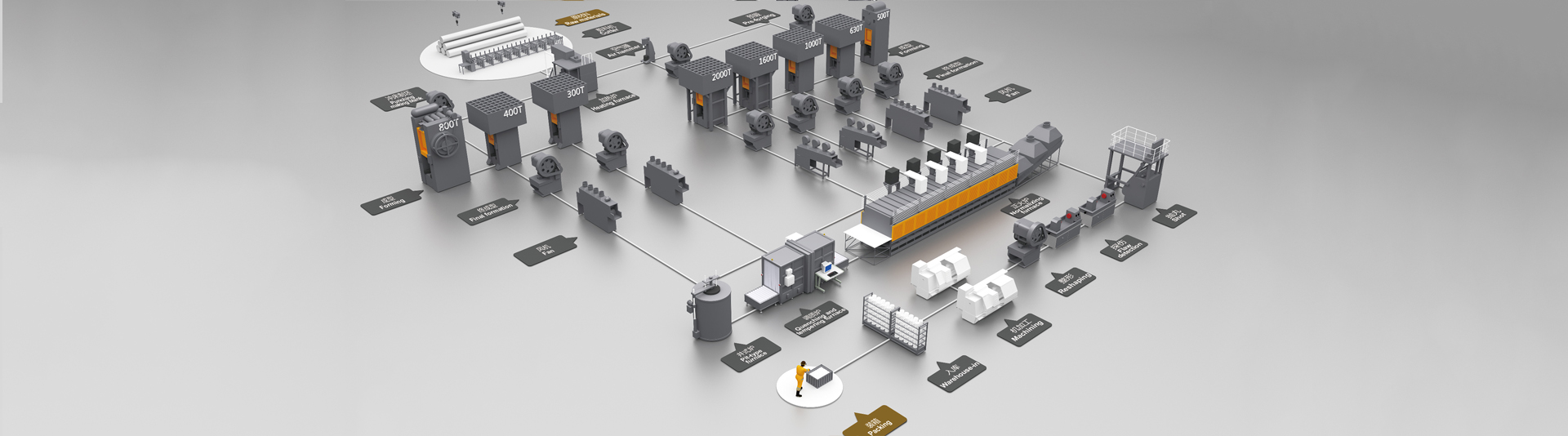

Perfect Quality

Perfect Quality Production Process

Production Process People Oriented

People Oriented Close to the Market

Close to the Market Focus on the Future

Focus on the Future